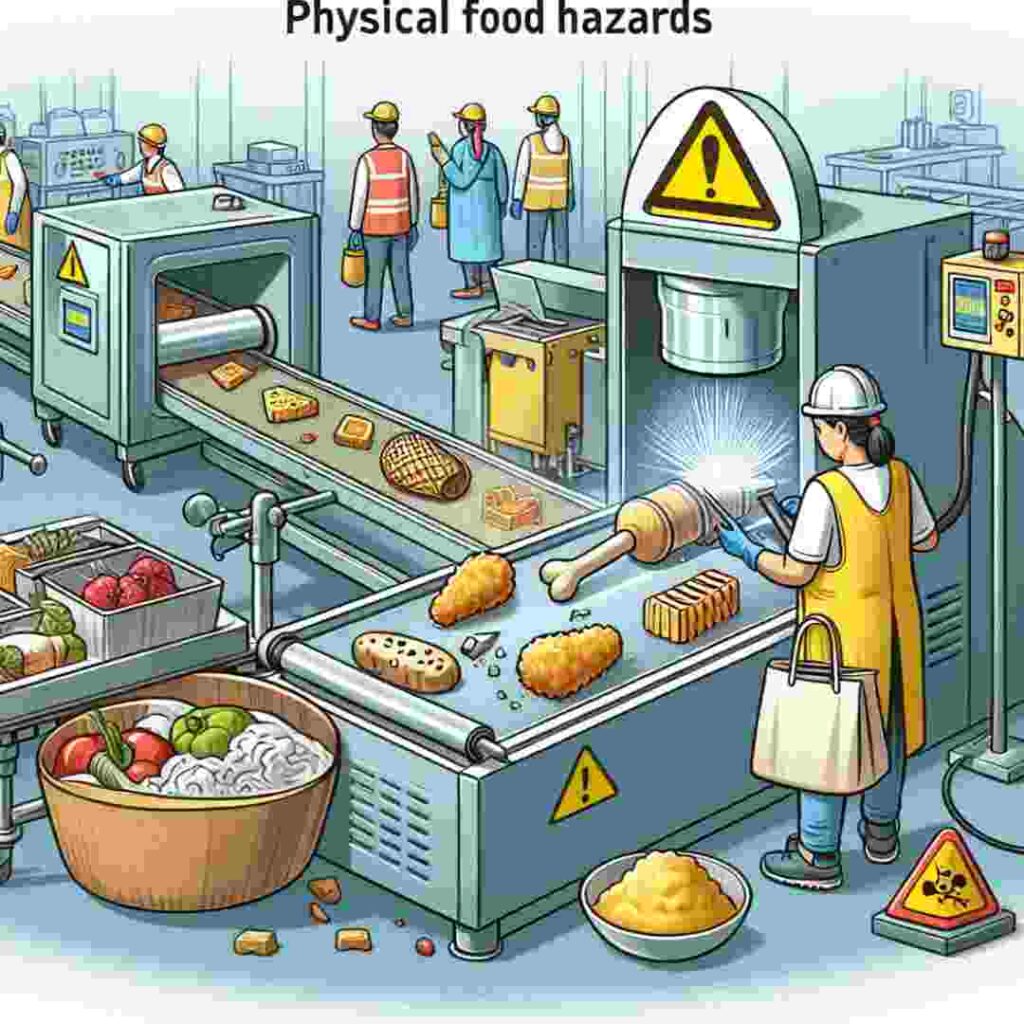

In the bustling world of food service, customer safety is paramount. Every restaurant owner, food service worker, and health inspector knows that maintaining high standards isn’t just about taste but trust. One critical aspect of this trust is preventing physical food hazards that could harm customers. We’ll explore practical methods for identifying and preventing these hazards in your establishment. Let’s ensure you remain at the top of your game, prioritizing safety without sacrificing quality.

Understanding Physical Food Hazards

Physical food hazards are foreign objects that accidentally enter food. These can range from glass shards to metal fragments, and each poses a significant risk to consumer safety. For restaurant owners, identifying these potential dangers is vital to maintaining a safe dining environment. Recognizing the types of physical hazards is the first step in establishing effective preventive measures.

Awareness is crucial. Items like jewelry, utensils, packaging materials, and even natural components, such as bones, can end up in food. Understanding where these hazards originate is vital in creating a safer kitchen. Regular training and education for food service workers can further enhance awareness and decrease the likelihood of accidents.

Preventive strategies must be comprehensive and systematic to be effective. Regular inspections, careful handling practices, and consistent communication ensure that potential hazards are swiftly identified and addressed. This proactive approach embodies a culture of safety that resonates throughout your operation.

The Importance of Staff Training

Well-trained staff are the first line of defense against physical food hazards. A rigorous training program should focus on the identification and prevention of common hazards, with an emphasis on real-world applications. Engaging training methods, such as hands-on practice and interactive seminars, help solidify the knowledge necessary for maintaining a safe kitchen environment.

Reinforcing these lessons through regular refreshers ensures that safety remains a priority. Workshops, drills, and ongoing assessments keep employees alert and prepared to face potential challenges. This continuous learning process cultivates a competent workforce that handles food safely and confidently.

Cultivating a safety-first mindset goes beyond basic training. Encouraging open communication and feedback allows staff to contribute their observations and suggestions for improvement. The kitchen becomes a collaborative and safe workspace with everyone actively participating in hazard prevention.

Maintaining Clean and Organized Workspaces

A clean and organized workspace is essential for minimizing risks associated with physical food hazards. Cluttered environments can increase the likelihood of foreign objects entering food. Implementing strict cleaning protocols and organizational systems can significantly reduce these risks.

Regular cleaning routines should be established and adhered to without fail. Comprehensive checklists and assigned responsibilities ensure every kitchen area receives its attention. Keeping surfaces clean helps prevent accidental contamination and the introduction of physical hazards.

The organization plays an equally important role. Labeled storage containers, designated areas for different tasks, and proper utensil management streamline operations and reduce the chance of mistakes. A well-organized kitchen not only enhances efficiency but also safeguards against potential hazards.

Equipment Maintenance and Inspection

Regular equipment maintenance and inspection are crucial in preventing physical food hazards. Machinery and tools that aren’t maintained properly can lead to dangerous malfunctions and introduce foreign objects into food. Establishing a routine maintenance schedule can mitigate these risks.

Inspecting equipment regularly ensures that any issues are identified and rectified before they become serious problems. Scheduling these inspections as part of the daily routine keeps them from being overlooked. Attention to detail during these evaluations is crucial in identifying the most minor potential hazards.

When issues are discovered, repairs and replacements should be conducted promptly. This proactive approach prevents minor problems from escalating into significant hazards. Ensuring that equipment is in top working condition is a foundational aspect of maintaining a safe food preparation environment.

Monitoring Food Preparation and Handling

Careful food preparation and handling monitoring are vital in preventing physical food hazards. Observing kitchen operations allows identifying risky behaviors and practices that might lead to contamination. Close supervision ensures that established safety protocols are followed diligently.

Consistent oversight during food preparation helps cultivate a culture of accountability. Employees are more likely to adhere to safety guidelines when they know their actions are being monitored. This vigilance encourages good habits and reduces the likelihood of accidents occurring.

Feedback from supervisors and managers should be constructive and supportive. Highlighting areas for improvement while recognizing good practices fosters a positive environment where safety is prioritized. Consistent communication around food safety helps reinforce its importance in daily operations.

Establishing Clear Safety Protocols

Clear and comprehensive safety protocols provide a roadmap for preventing physical food hazards. These guidelines should be documented, easily accessible, and regularly updated to reflect industry best practices. Establishing a robust framework ensures every Employee understands their role in maintaining a safe kitchen.

Protocols should cover all aspects of food preparation, from receiving and storage to cooking and plating. Detailed instructions leave no room for ambiguity, ensuring everyone is on the same page. Consistency in protocol adherence is critical to maintaining a hazard-free environment.

Encouraging staff to familiarize themselves with these protocols and seek clarification promotes a safety culture. Employee buy-in is critical to the success of any safety initiative, and involving them in creating and refining protocols fosters a sense of ownership.

Utilizing Technology for Safety

Modern technology offers innovative solutions for preventing physical food hazards. From advanced monitoring systems to cutting-edge equipment, leveraging technology enhances safety protocols and reduces human error. Integrating these advancements into daily operations can revolutionize hazard prevention.

Automated systems provide real-time monitoring and alerts, enabling rapid response to potential hazards. These technologies ensure that food safety remains uncompromised, even during busy periods. Investing in reliable systems safeguards both the business and its customers.

Training staff to effectively use technology is essential. Proper instruction ensures that employees are comfortable and confident in utilizing these tools to their full potential. Seamless integration of technology into everyday practices enhances both efficiency and safety.

Conducting Regular Safety Audits

Regular safety audits are a critical component of maintaining a hazard-free kitchen. These evaluations provide an objective assessment of current practices and identify areas for improvement. Routine audits ensure that safety remains a top priority and that protocols are effective.

Conducting thorough audits involves reviewing every aspect of kitchen operations, from equipment functionality to Employee practices. Every detail should be noticed. Comprehensive evaluations provide valuable insights into potential weaknesses and opportunities for enhancement.

Acting on audit findings is critical to continuous improvement. Implementing recommended changes and addressing identified issues demonstrates a commitment to safety. Regularly revisiting and refining safety protocols keeps them relevant and effective over time.

Encouraging a Safety-First Culture

A safety-first culture empowers employees to prioritize hazard prevention in their daily tasks. Encouraging this mindset involves fostering an environment where safety is valued and recognized. By making safety a core aspect of your business, you inspire employees to take ownership of maintaining a safe workplace.

Recognition and rewards for safe practices motivate employees to uphold safety standards. Celebrating achievements and milestones reinforces the importance of hazard prevention. Positive reinforcement encourages a proactive approach to safety across the entire Team.

Open communication channels ensure that concerns and suggestions are heard and addressed promptly. Encouraging dialogue around safety fosters collaboration and innovation, leading to more effective solutions. A unified effort toward hazard prevention strengthens the overall safety culture.

Collaborating with Health Inspectors

Collaborating with health inspectors enhances your ability to prevent physical food hazards. These experts provide valuable insights and guidance to ensure regulations and safety standards compliance. Establishing a positive relationship with inspectors benefits both your business and your customers.

Regular consultations with health inspectors help identify potential risks and improve safety measures. Their expertise offers a fresh perspective and valuable recommendations. Engaging with inspectors proactively demonstrates your commitment to maintaining a safe environment.

Implementing inspector feedback promptly ensures that your operations align with industry standards. Responsiveness to their advice reflects positively on your business and reinforces your dedication to customer safety. Building trust with inspectors fosters a collaborative partnership.

Building Community Awareness

Building community awareness around food safety enhances your reputation as a responsible business. Sharing your commitment to preventing physical food hazards fosters customer trust and confidence. Transparent communication around safety initiatives strengthens relationships with the community.

Engaging with customers through educational campaigns and initiatives raises awareness about food safety. Providing resources and information empowers consumers to make informed choices. Active participation in community events further demonstrates your dedication to safety.

Encouraging customer feedback and involvement in safety efforts reinforces your commitment to their well-being. Valuing their input and addressing their concerns proactively builds trust and loyalty. Open dialogue with the community strengthens your position as a reliable and responsible establishment.

Frequently Asked Questions

1. What are physical food hazards, and how can they occur?

Physical food hazards refer to foreign objects or substances in food that can cause harm when ingested, such as metal shards, glass pieces, or bones. These hazards can occur at any stage of food production, from raw material handling to final preparation, due to cross-contamination, equipment malfunction, or improper handling.

2. How often should safety audits be conducted in a kitchen?

Safety audits should ideally be conducted regularly to ensure ongoing compliance and promptly address potential hazards. Depending on the size and nature of your operations, this could mean monthly, quarterly, or bi-annual audits.

3. What technologies are recommended for preventing physical food hazards?

Recommended technologies include automated monitoring systems, metal detectors, X-ray scanners, and advanced filtration systems. These tools help detect and eliminate potential hazards efficiently, reducing reliance on manual inspections.

4. How can we encourage employees to adhere to safety protocols?

Encouragement can be achieved by involving employees in creating and refining safety protocols, recognizing and rewarding safe practices, and fostering open communication about safety concerns and solutions.

5. Why is collaboration with health inspectors essential?

Health inspectors bring expertise and a fresh perspective to your safety practices. Collaborating with them helps ensure that your operations meet regulatory standards and allows for continuous improvement in hazard prevention measures.

6. How does building community awareness about food safety benefit a business?

Building community awareness enhances your reputation as a responsible and trustworthy establishment. It fosters customer confidence and loyalty by showing proactive efforts to ensure their well-being, ultimately strengthening your relationship with the community.

Conclusion

Preventing physical food hazards from injuring customers requires a multifaceted approach that involves staff training, equipment maintenance, and collaboration with experts. By prioritizing safety and implementing comprehensive protocols, you create a secure dining experience for your customers. The benefits of this approach extend beyond safety, enhancing your reputation and building trust within the community. To further explore safety and prevention strategies tailored to your establishment, consider consulting with industry professionals or attending specialized workshops. Your commitment to safety protects your customers and strengthens your business in the long run.